When working on a project that involves sensitive equipment or machinery, choosing the right enclosure is crucial. Custom enclosures can provide the exact protection and functionality you need. Whether you’re in the electronics, industrial, or automotive industry, designing the right enclosure can make a big difference in the performance and longevity of your equipment. But what factors should you consider when designing custom enclosures?

Why Custom Enclosures Are Important

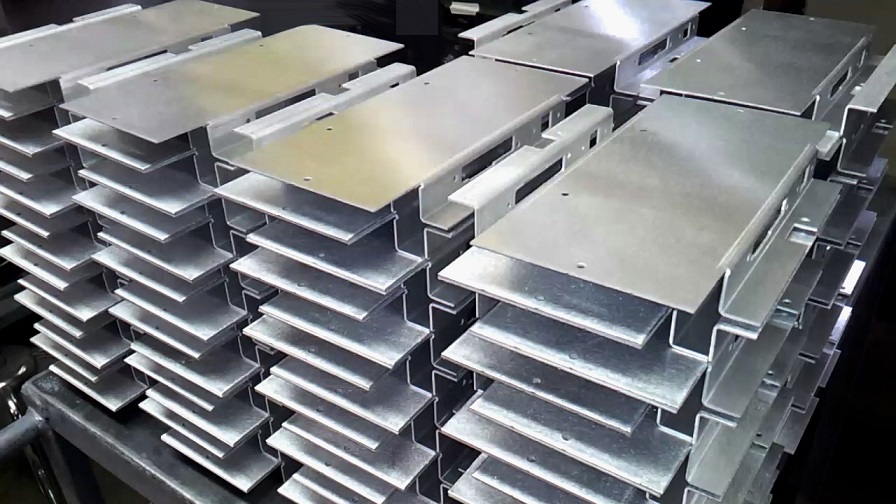

Off-the-shelf enclosures often fail to meet the specific requirements of many projects. Custom enclosures are tailored to your equipment, ensuring the perfect fit. With a custom fabricated metal products service in Alberta, you can create enclosures that are designed to handle unique conditions, such as extreme temperatures, moisture, or electrical interference. These custom designs ensure that your equipment stays protected and performs at its best, even in challenging environments.

Understanding the Design Process

The process of designing a custom enclosure typically begins with understanding the equipment it will house. Before you contact an enclosure fabrication service in Alberta, it’s essential to gather the necessary information about the equipment’s dimensions, functionality, and environmental factors. For example, consider:

- Size and Shape: The enclosure must have enough space for your equipment, cables, and any additional components. Proper space allocation is essential for easy installation and maintenance.

- Material Selection: The material used for the enclosure is important. Common options include metals like stainless steel or aluminum, which offer strength and durability. You’ll need to choose materials that can withstand environmental conditions such as moisture, corrosion, or high temperatures.

- Ventilation and Cooling: For electronic or industrial equipment that generates heat, proper ventilation is crucial. Custom enclosures can include ventilation holes or fans to ensure that your equipment doesn’t overheat.

- Accessibility: It’s important to design enclosures that allow easy access for maintenance and repair. Doors, panels, or removable sides can be included to allow workers to safely and quickly reach the equipment.

Material Choices for Custom Enclosures

Choosing the right material for your custom enclosure is a critical part of the design process. Different materials offer different benefits, so you need to select the one that meets the demands of your project. Common materials for custom enclosures include:

- Aluminum: Lightweight and resistant to corrosion, aluminum is a popular choice for enclosures used in harsh environments. It also offers excellent heat dissipation, which is vital for electronic equipment.

- Stainless Steel: If your equipment is exposed to extreme temperatures or harsh chemicals, stainless steel may be the best choice. It’s strong, durable, and highly resistant to corrosion.

- Plastic: For lightweight applications, plastic can be used. It’s often used for smaller enclosures or when electrical isolation is necessary. However, plastic may not be suitable for heavy-duty industrial applications.

- Fiberglass: Fiberglass is known for its strength and weather resistance. It’s often used for outdoor enclosures that need to withstand the elements.

Ensuring Compliance and Safety

When designing custom enclosures, safety and compliance are key considerations. Different industries have specific regulations regarding safety, such as electrical safety standards or environmental protections. A well-designed custom enclosure can help ensure that your project meets the necessary regulatory standards.

For example, enclosures that house electrical equipment need to comply with industry standards such as IP (Ingress Protection) ratings, which define how well the enclosure protects against dust and water ingress. Similarly, if your equipment is used in hazardous environments, you may need to design enclosures that protect against explosive gases or chemicals.

An enclosure fabrication service in Alberta can help ensure your custom enclosures meet these standards, keeping your equipment safe and compliant with local regulations.

Why Work with a Professional Fabrication Service?

Creating custom enclosures requires expertise in both design and manufacturing. Working with a professional enclosure fabrication service in Alberta offers several benefits:

- Expert Design Assistance: Professional services have experienced engineers who can help you design the ideal enclosure for your equipment. They can provide valuable advice on materials, size, and features.

- Advanced Manufacturing Techniques: Professional fabricators use advanced tools and equipment, such as CNC machines, to create accurate and durable enclosures.

- Custom Features: Whether you need specific cutouts, ventilation systems, or mounting points, a professional service can provide the custom features your project requires.

The Role of CNC Turret Punch in Custom Enclosures

In the fabrication of custom enclosures, tools like the CNC turret punch can make a significant difference in the precision and quality of the final product. A CNC turret punch uses computer-controlled machinery to precisely cut and shape materials, ensuring that every part of the enclosure is accurate to the design specifications. This not only improves the overall quality of the enclosure but also reduces production time and costs.

Conclusion

Designing a custom enclosure for your project involves more than just picking a box for your equipment. It requires careful planning, material selection, and design considerations to ensure your enclosure protects your equipment while meeting safety standards. Working with an enclosure fabrication service in Alberta can help guide you through this process and ensure that your enclosures are built to meet your exact needs. By combining the right materials with precise fabrication techniques, your custom enclosures will provide the protection and functionality your equipment requires for success.