Maintaining clean environments is critical in the fast-evolving fields of pharmaceuticals, microelectronics, aerospace, and precision manufacturing. Cleanroom constructions are indeed the unsung heroes behind the production of important drugs, semiconductor chips, and even aerospace components. Players like Quantum Pharmatech are pioneers in crafting the best cleanrooms to meet the diverse manufacturing requirements.

Understanding the basics of cleanrooms:

In order to maintain a very controlled environment, the cleanrooms will strive to keep the dust particles and the aerosols away. These rooms are classified according to the number of particles per cubic meter. They also have ISO classifications that rangers between ISO 1 and 9. A cleanroom is also required to meet specific requirements as per the industry and its applications. This is the reason why cleanroom designs do not follow a one-size-fits-all approach. But a tailored solution will involve engineering precision and advanced planning, and compliance with cleanroom standards such as ISO, USP, GMP, etc.

Importance of strategic cleanroom designs:

Cleanroom designs play a critical role in ensuring regulatory compliance, long-term sustainability, and operational efficiency.

- A cleanroom will prevent contamination in the room with the help of controlled airflow and pressure differences.

- The cleanroom will facilitate routine cleaning and maintenance.

- The cleanroom will support energy efficiency and ensure ergonomics and safety for personnel.

- It should accommodate future expansion and changes in equipment.

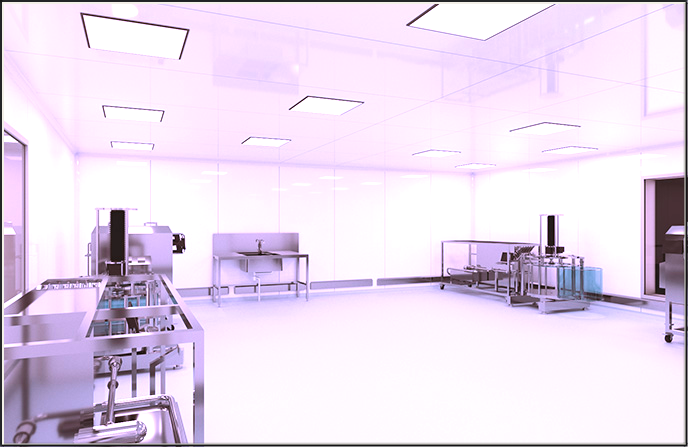

Cleanroom construction should understand that every single detail matters, from ceiling types to wall materials and from HVAC systems to airlocks. Their design will take everything into account, starting from particle flow and personnel movement to equipment placement and maintenance, thus ensuring optimum performance.

Quantum cleanrooms – leaders in cleanroom construction

Quantum Cleanrooms is a trusted name when it comes to cleanroom construction. For years, it has been providing high-performance cleanroom construction across various industries. Be it sterile manufacturing-based facilities, a microchip fabrication plant, or a hospital-compounding pharmacy, Quantum offers turnkey cleanroom projects that are efficient, scalable, and compliant.

- Integrated Design-Build Approach

Quantum Cleanrooms offers turnkey solutions from conception to commissioning. Their integrated approach ensures that cleanroom design, engineering, construction, validation, and maintenance are integrated as a one-stop unit for complete accountability and a streamlined process.

- All Standards Know-How

Quantum Cleanrooms is very conversant with industry-specific requirements and international standards, including ISO 14644, GMP, FDA, and USP 797/800, and as a result, their cleanrooms always meet the need of compliance and often surpass it.

- Custom-Fitted Solutions

Every client has different needs. Quantum takes time to learn the specifics of their processes, regulatory requirements, and workflow demands before designing a cleanroom made-to-measure for them.

- Sturdy Materials & Modular Systems

Quantum’s cleanroom designs use superior-quality modular wall and ceiling systems, stainless steel furniture, and HEPA/ULPA filters. This modular system makes maintenance and upgrades easy and cost-effective down the line.

FAQ:

What are the applications of cleanrooms?

Cleanrooms have been successful across diverse industries, including biotech, pharmaceuticals, healthcare, electronics, defence, and aerospace.

Why Choose Quantum Cleanrooms?

Cleanrooms are high-stakes constructions in which an error in design or construction may lead to contamination, regulatory penalties, product recalls, or an outright threat to human life. Hence, partnering with an expert like Quantum Cleanrooms is not just advisable but an absolute must.

- Documented Experience: A proven record of dozens of successful cleanroom installations in demanding industries.

- Technical Expertise: A multidisciplinary group of certified engineers, architects, and project managers.

- Complete service of cleanrooms that includes the time from their commissioning and their complete maintenance.

- Compliance Assurance: Cleanrooms that are ready from the first day to be inspected and certified.

Final Thoughts

Cleanroom construction and design are highly technical pursuits that require an understanding of contamination control, environmental engineering, and regulatory compliance. This is an emerging field in which Quantum Cleanrooms has become a trusted name for custom, efficient, and fully compliant cleanroom solutions.