Whether you’re sailing the open ocean or navigating a quiet lake, the heart of any boat is its marine engine. Behind every smooth ride is a complex network of marine engine parts working together to deliver power, control, and reliability on the water.

In this blog, we’ll break down the key marine engine components, their functions, and why proper maintenance is essential.

What Is a Marine Engine?

A marine engine is specially designed to power watercraft. These engines face unique challenges — including saltwater exposure, constant vibration, and external cooling from water — making them very different from automobile engines.

There are several types of marine engines:

-

Inboard engines (built into the hull)

-

Outboard motors (mounted on the transom)

-

Stern drives (inboard/outboard hybrids)

-

Jet drives (used in high-speed or shallow-water vessels)

Let’s explore the key components that keep these engines running efficiently.

Key Marine Engine Parts and Their Functions

1. Cylinder Block

The main structure of the engine, housing the cylinders, pistons, and crankshaft. It’s built to endure high pressure and marine conditions.

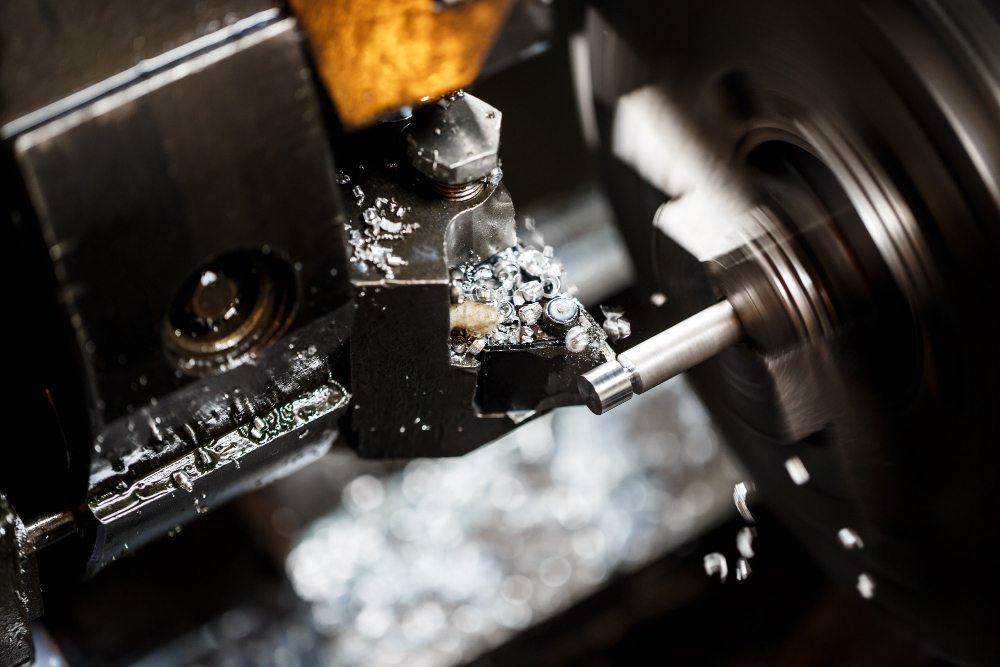

2. Pistons and Connecting Rods

These move within the cylinders to convert combustion energy into mechanical movement that powers the boat.

3. Crankshaft

Transforms the pistons’ vertical movement into rotational force, ultimately turning the propeller.

4. Camshaft

Controls the timing of the opening and closing of the intake and exhaust valves.

5. Valves and Valve Springs

Manage airflow into the engine and the release of exhaust gases. They’re essential for maintaining efficient combustion.

6. Cooling System Components

-

Water pump: Draws in raw water (lake or seawater) to help cool the engine

-

Heat exchanger: Transfers heat from the engine coolant to the raw water

-

Thermostat: Maintains proper engine temperature

7. Fuel System

Includes components such as the fuel pump, filters, injectors (or carburetor), and fuel lines. It delivers fuel efficiently to the combustion chamber.

8. Ignition System

Comprises spark plugs, ignition coils, and timing systems. It initiates combustion in gasoline-powered marine engines.

9. Exhaust System

Expels burned gases safely out of the engine. Marine exhaust systems are often water-cooled to prevent overheating and reduce engine noise.

10. Lubrication System

Uses oil pumps, filters, and passages to reduce friction between moving parts and prolong engine life.

11. Propeller and Drive System

Transfers the engine’s power to the water through the gearcase, propeller shaft, and propeller itself.

12. Electrical and Control Systems

Includes the battery, alternator, starter motor, and sometimes an Engine Control Unit (ECU) in modern systems.

Why Proper Maintenance Matters

Marine engines are exposed to harsher environments than land-based engines. Saltwater, moisture, and vibration all contribute to faster wear and corrosion. Proper maintenance of each part is crucial for performance and safety. Key practices include:

-

Flushing the engine after saltwater use

-

Changing engine oil and filters regularly

-

Replacing worn spark plugs and fuel filters

-

Using only marine-grade parts

OEM vs. Aftermarket Marine Parts

OEM (Original Equipment Manufacturer) parts are built to the exact specifications of the engine manufacturer, offering guaranteed fit and performance.

Aftermarket parts may be more affordable and widely available but can vary in quality.

When replacing critical components like impellers or thermostats, reliability and material quality should be top priorities.

Conclusion

Marine engines are built for performance in extreme environments, and every component plays a role in ensuring reliability and safety on the water. From the crankshaft to the cooling system, understanding how your marine engine works — and how to care for it — can save you time, money, and trouble.