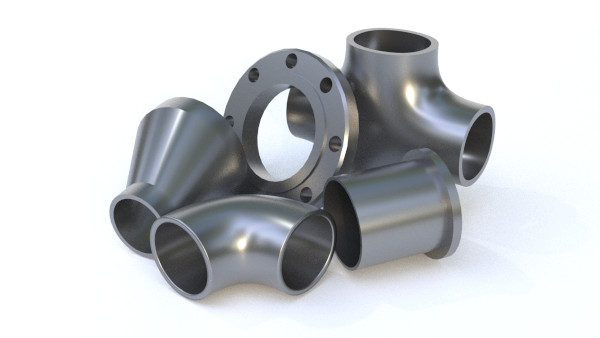

Titanium pipe fittings are widely used in the aerospace and marine industries due to their excellent properties. These fittings offer strength, durability, and resistance to harsh environments, making them a top choice for critical applications.

The aerospace and marine sectors require materials that can withstand extreme conditions while maintaining efficiency and reliability. Titanium pipe fittings have proven to be highly effective in these industries due to their unique advantages over other materials such as steel, aluminum, and copper.

1. High Strength and Lightweight

Titanium pipe fittings are known for their high strength-to-weight ratio. They are as strong as steel but weigh much less, which helps reduce the overall weight of aircraft and marine vessels. This weight reduction improves fuel efficiency and performance.

In aerospace applications, lighter components contribute to increased payload capacity and improved aerodynamics. In marine vessels, reduced weight enhances fuel economy, which is a crucial factor for both commercial and military ships.

2. Excellent Corrosion Resistance

One of the biggest advantages of titanium pipe fittings is their resistance to corrosion. In marine environments, these fittings can withstand exposure to saltwater without rusting or degrading. This is particularly important for submarines, offshore drilling platforms, and ships, where constant exposure to moisture and salt can quickly corrode other materials.

In aerospace applications, titanium resists oxidation and other chemical reactions, ensuring long-term reliability. This makes it an ideal choice for aircraft hydraulic systems, fuel lines, and structural components that must endure varying atmospheric conditions.

3. Heat and Temperature Resistance

Titanium pipe fittings can withstand extreme temperatures without losing their strength. In aerospace applications, they handle high temperatures during flights and re-entry, making them ideal for jet engines, exhaust systems, and structural components.

In marine industries, they perform well under varying temperature conditions, ensuring safety and durability. Ships and submarines operate in extreme cold and heat, and titanium fittings help maintain structural integrity even under these conditions.

4. Long Service Life

Due to their strength and resistance to corrosion, titanium pipe fittings last much longer than other materials. This reduces the need for frequent replacements and lowers maintenance costs over time.

In both aerospace and marine industries, regular maintenance and part replacements can be expensive and time-consuming. Using titanium fittings significantly extends the lifespan of essential systems, reducing downtime and ensuring smooth operations.

5. Compatibility with Other Materials

Titanium pipe fittings are compatible with different metals and materials used in aerospace and marine structures. They do not cause galvanic corrosion when used with other metals, making them ideal for mixed-material systems.

For example, titanium fittings are used in aircraft where they connect with aluminum or steel components without causing electrochemical reactions. Similarly, in marine applications, they can be used alongside copper or stainless steel piping without the risk of accelerated corrosion.

6. Non-Magnetic and Biocompatible

Titanium is a non-magnetic material, making it useful in certain aerospace applications where magnetic interference needs to be avoided. This is especially important for aircraft navigation systems, radar equipment, and submarine stealth technology.

Additionally, titanium is biocompatible, meaning it is safe for use in environments where human interaction is involved. This property has led to its use in medical-grade marine equipment and aerospace life-support systems.

7. Environmental Benefits

Titanium pipe fittings contribute to sustainability in both aerospace and marine industries. Their long lifespan reduces waste, and their lightweight nature helps decrease fuel consumption, lowering carbon emissions.

Many aerospace and marine companies are now prioritizing environmentally friendly solutions, and titanium’s recyclability makes it an attractive option. Once decommissioned, titanium components can be repurposed, further reducing environmental impact.

Conclusion

Titanium pipe fittings are essential for aerospace and marine industries due to their strength, corrosion resistance, and durability. They help improve performance, reduce maintenance, and ensure long-lasting reliability.

With their ability to withstand extreme temperatures, resist corrosion, and reduce overall weight, titanium pipe fittings offer unparalleled benefits in demanding environments. As technology continues to advance, the use of titanium in aerospace and marine applications will only increase, further solidifying its role as a key material in these industries .