Outdated insulation can pose serious threats to indoor air quality. As insulation materials degrade over time, they can release particles, absorb moisture, grow mold, or emit harmful chemicals into the air you breathe. These contaminants often spread through your home’s ventilation systems, affecting overall air freshness and triggering respiratory issues, especially in individuals with asthma, allergies, or other sensitivities.

The core concern is simple: old insulation no longer performs like it used to. Beyond losing its energy-saving function, it can actively pollute your living environment. This article will explore how insulation age impacts air quality, which materials are most concerning, and how to decide if replacement is necessary.

Why Old Insulation Affects Air Quality

Most insulation materials were designed primarily to control heat loss, not to safeguard indoor air. Over decades, insulation exposed to moisture, pests, or temperature swings can start to decay. As the structure weakens, particles break loose and drift into the surrounding air. These airborne particles often include dust, fiberglass shards, mold spores, or chemical residue—depending on the insulation type and its condition.

Moisture is another key factor. When water seeps into insulation, it creates an ideal breeding ground for mold. Mold spores can easily become airborne, settle into ducts, or cause unpleasant odors that linger in the home. In older homes, insulation may even contain outdated or hazardous materials, such as vermiculite contaminated with asbestos or spray foam containing high levels of VOCs (volatile organic compounds).

If you’ve noticed strange odors, persistent dust, unexplained allergy symptoms, or humidity imbalances, outdated insulation may be contributing to these issues—especially in attics, crawl spaces, or wall cavities that haven’t been inspected in years.

How Different Insulation Materials Impact Indoor Air

The impact of insulation on air quality varies by material. Some degrade faster, while others resist moisture better or emit fewer gases. Here’s how the most common types compare:

| Insulation Type | Age Risk (Years) | Common Air Quality Issues | Moisture Retention | Mold Risk | VOC Release |

| Fiberglass (batts) | 15–20 | Dust, glass fiber particles | Medium | Medium | Low |

| Cellulose | 10–15 | Mold spores, chemical residues | High | High | Medium |

| Mineral Wool | 20+ | Dust, fiber fragments | Low | Medium | Low |

| Spray Foam (old) | 20+ | VOC release from breakdown | Low | Low | High |

| Vermiculite (pre-1990) | Any | Asbestos contamination | Low | Medium | Very High |

Cellulose insulation, often made from recycled newspaper, tends to absorb moisture and degrade quickly, leading to high mold risk. Fiberglass may shed microscopic glass fibers, especially as it deteriorates, which can cause irritation if inhaled. Older spray foam products sometimes emit lingering chemical fumes if not mixed or cured correctly. Mineral wool is more stable but still vulnerable to dust accumulation over time.

One of the most concerning materials is vermiculite, especially if installed before the 1990s. Vermiculite from certain mines contains asbestos—a known carcinogen. If disturbed, the fibers can become airborne and remain in the lungs for years, creating long-term health risks.

Key Technical and Environmental Considerations

The integrity of insulation isn’t just a comfort or energy concern—it’s also measurable in ways that directly impact health. Several environmental and material indicators can help assess whether your insulation may be contributing to air quality problems.

| Specification | Safe Range or Standard | Risk When Outdated |

| R-Value Degradation | < 10% drop over 10 years | Increased energy use, HVAC stress |

| Airborne Fiber Emission | ≤ 0.1 fibers/cc (OSHA) | Irritation of lungs and eyes |

| Moisture Content | ≤ 15% for insulation materials | Mold growth likely if >20% |

| Formaldehyde Emissions | ≤ 0.03 ppm (EPA recommended) | Triggers headaches and nausea |

| Mold Spore Count (Indoor) | < 500 spores/m³ | Above 1000 indicates contamination |

As insulation degrades, its R-value (thermal resistance) decreases, making it harder to maintain consistent temperatures. This stresses your HVAC system, which also has to circulate air contaminated by insulation debris. The U.S. EPA classifies formaldehyde and airborne fiberglass as hazardous when inhaled in excess, especially in enclosed, poorly ventilated spaces.

What You Should Know Before Taking Action

Before deciding to replace or remediate insulation, it’s important to understand several factors that can influence both the urgency and the type of intervention you may need.

Start by confirming the age and type of insulation used in your home. Homes built before 1990 often contain materials now considered hazardous, such as vermiculite or early-generation spray foam. If no upgrades have been made since then, a professional inspection is strongly advised.

The local climate also plays a role. High humidity or frequent temperature swings accelerate insulation breakdown. Homes in coastal or wet environments may see faster mold growth, while colder climates lead to cracks and air gaps that increase pollutant movement.

Your home’s ventilation also matters. If your HVAC system is outdated or your ducts are leaky, it will spread contaminants more easily. Dust, mold, and fiber particles can accumulate in vents and recirculate constantly.

Health risk tolerance is another key issue. Families with young children, seniors, or those with respiratory conditions should err on the side of caution. Even low-level exposure to insulation particles or fumes can worsen symptoms over time.

Finally, weigh the cost of inaction. Poor air quality leads to higher medical expenses, HVAC repairs, and energy bills. In contrast, upgrading insulation—though an upfront investment—improves air quality, comfort, and long-term property value.

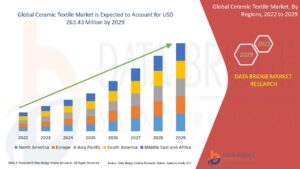

Market Snapshot on Insulation and Air Quality

According to the EPA, indoor air can be two to five times more polluted than outdoor air. Insulation degradation is one of the top five contributors. A 2023 study by the Department of Energy found that nearly 40% of U.S. homes still have insulation beyond its recommended service life. These homes are at a higher risk of poor air quality, mold exposure, and energy inefficiency.

Answers to Common Questions

How do I know if insulation is affecting air quality?

Symptoms such as chronic coughing, sneezing, eye irritation, or musty odors—especially when the HVAC system runs—can signal airborne pollutants from old insulation. Professional air testing can confirm the source.

Can I remove insulation myself?

It depends on the material. If you suspect asbestos or mold, do not attempt removal yourself. For safer materials like modern fiberglass, attic removal may be possible with proper protection and containment.

Does insulation affect my HVAC system?

Yes. Dust and particles from insulation can clog air filters, reduce system efficiency, and circulate allergens. Older systems may also lack proper filtration to trap these contaminants.

Is modern insulation safer?

Today’s insulation products are generally safer, especially when labeled low-VOC or formaldehyde-free. Materials like mineral wool and closed-cell spray foam offer improved moisture resistance and better air sealing.

How often should I inspect insulation?

Inspection every 7–10 years is ideal. However, homes with visible signs of wear, recent leaks, or occupant health issues may need immediate assessment.

Make the Right Decision

If your insulation is over 15 years old, has been exposed to moisture, or was installed using materials no longer considered safe, it may be harming your air quality. You don’t need to wait for visible mold or illness to take action. Indoor air pollution often builds silently, becoming noticeable only after long-term exposure.

A home energy audit or insulation inspection can give you a clearer picture of what’s happening behind your walls or in your attic. Whether you choose full replacement, targeted removal, or improved ventilation, addressing insulation quality is a critical step toward creating a healthier living environment.

Topic FAQ

What health issues are linked to degraded insulation?

Respiratory irritation, skin rashes, headaches, and allergic reactions are common, especially from mold, fiberglass, or VOCs.

Is old insulation always harmful?

Not always, but it becomes risky once it degrades, absorbs moisture, or releases particles. Age, type, and exposure all factor in.

Can new insulation eliminate air quality issues?

It helps significantly, but also ensure your HVAC system is clean and your home is well-sealed and ventilated.

Are insulation upgrades covered by tax credits?

Yes. Many local and federal programs offer credits for energy-efficient upgrades, including insulation.

How do I choose insulation with low air quality risk?

Look for formaldehyde-free, low-VOC certified options like mineral wool or modern spray foams applied by professionals.

Reviewer:

Sophia White has 8 years of experience in spray foam insulation. She reviewed this post and gave clear guidance on aligning business messaging with what customers actually care about.