The global electrolyser market size reached a value of about USD 461.85 million in 2024. The market is further estimated to grow at a compound annual growth rate (CAGR) of 27.30% during the forecast period of 2025-2033, reaching a value of around USD 4,054.68 million by 2033. This remarkable growth is driven by the increasing demand for green hydrogen and advancements in electrolyser technology. As countries and industries seek sustainable energy solutions, electrolysers, which are crucial for the production of hydrogen through electrolysis, are emerging as a key component in the global transition to clean energy.

In this blog post, we will explore the key factors driving the growth of the electrolyser market, the different types of electrolysers, and their applications, as well as the regional dynamics and competitive landscape shaping the market’s future.

Market Overview

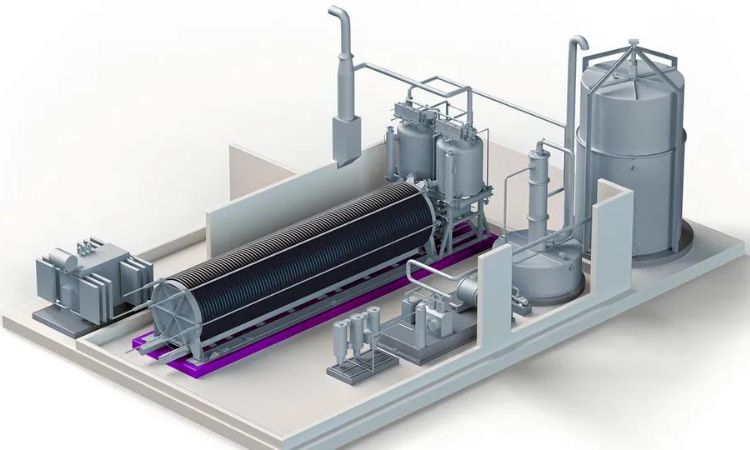

Electrolysers are devices that use electricity to split water molecules into hydrogen and oxygen, a process known as electrolysis. The hydrogen produced through electrolysis is known as green hydrogen when renewable energy sources power the process. Green hydrogen is gaining increasing importance as a clean energy source, especially for industries such as transportation, power generation, and industrial feedstock, where it can replace fossil fuels and reduce carbon emissions.

As the world moves towards decarbonization, the electrolyser market is experiencing a significant surge in demand. Electrolysers are not only essential for hydrogen production but are also seen as key enablers of energy transition by facilitating the integration of renewable energy sources, especially in sectors that are challenging to decarbonize.

Market Segmentation by Product Type

Alkaline Electrolyser

Alkaline electrolysers are one of the most widely used types due to their cost-effectiveness and reliability. These electrolysers use an alkaline solution, such as potassium hydroxide, as the electrolyte, which helps in the separation of water into hydrogen and oxygen. Alkaline electrolysers have been in use for many decades, and their large-scale deployment in industries like power generation and transportation is boosting their market presence.

The key advantage of alkaline electrolysers is their scalability. They can be deployed for both small and large-scale hydrogen production projects. This makes them ideal for a wide range of applications, including hydrogen fueling stations and industrial hydrogen supply. The growing demand for clean hydrogen across multiple sectors will continue to drive the adoption of alkaline electrolysers in the coming years.

Solid Oxide Electrolyser

Solid oxide electrolysers (SOEs) operate at high temperatures and use a solid ceramic electrolyte. SOEs offer a high degree of efficiency due to their ability to operate at elevated temperatures, which reduces the overall energy input required for electrolysis. These electrolysers are particularly suited for integration with renewable energy sources, such as solar and wind power, where they can help manage intermittent power supply by storing energy in the form of hydrogen.

SOEs are increasingly being deployed for large-scale hydrogen production and for industrial processes where high efficiency and low emissions are critical. The ability to utilize heat from industrial processes, such as those in steel production, makes SOEs an attractive option for sectors focused on decarbonization.

PEM Electrolyser

Proton exchange membrane (PEM) electrolysers are more advanced and operate at a higher efficiency compared to alkaline electrolysers. They use a solid polymer membrane as the electrolyte and can generate high-purity hydrogen with faster response times. PEM electrolysers are particularly suitable for applications requiring quick start-up times and the ability to handle fluctuating power inputs from renewable sources like wind and solar.

The demand for PEM electrolysers is expected to rise significantly in the transportation sector, particularly for fueling hydrogen-powered vehicles, such as buses, trucks, and trains. The ability to produce high-quality hydrogen on-site at fueling stations is a major growth factor for PEM electrolysers.

Market Segmentation by Capacity

Less than 500 kW

Electrolysers with a capacity of less than 500 kW are typically used for small-scale hydrogen production. These electrolysers are well-suited for decentralized hydrogen generation applications, such as remote areas, small industrial processes, and residential energy systems. The increasing need for localized and off-grid clean energy solutions is expected to drive the growth of small-scale electrolysers.

Small-capacity electrolysers are also being deployed in applications like small hydrogen fueling stations and as backup power systems in remote locations. These systems are often powered by renewable energy sources, further enhancing their appeal as green solutions.

500 kW – 2 MW

Electrolysers in the 500 kW to 2 MW range are used for commercial-scale hydrogen production. These systems are capable of producing significant amounts of hydrogen for industrial uses, including power generation, energy storage, and transportation applications. The mid-range electrolysers are commonly found in hydrogen refueling stations, where they support hydrogen fuel cell vehicles.

With the growing interest in fuel-cell technology for transportation, the demand for these mid-capacity electrolysers is expected to increase rapidly. Additionally, their ability to work with renewable energy sources such as wind and solar will support their adoption in large-scale hydrogen production projects.

Above 2 MW

Large-capacity electrolysers (above 2 MW) are used in large-scale hydrogen production projects, particularly in industries requiring vast amounts of hydrogen, such as power generation and heavy manufacturing. These systems can produce hydrogen for grid-scale energy storage and decarbonization of energy-intensive industries.

The growing need for industrial-scale hydrogen production as part of decarbonization efforts is driving the demand for large electrolysers. These systems are critical for supporting national or regional hydrogen infrastructure and are expected to play a key role in the future energy mix.

Market Segmentation by Application

Transportation

The transportation sector is one of the largest consumers of hydrogen, particularly in fuel cell vehicles (FCVs) that run on hydrogen instead of conventional fuels. Electrolysers play a vital role in producing the hydrogen required for these vehicles. The deployment of hydrogen fueling stations, powered by electrolysers, is critical to the expansion of the hydrogen mobility infrastructure.

The growth in the number of hydrogen-powered vehicles, coupled with government incentives for green transportation, will drive the demand for electrolysers in the transportation sector. Hydrogen-powered buses, trucks, and trains are expected to become more common as governments invest in hydrogen infrastructure to reduce emissions and promote clean energy.

Power Generation

Electrolysers are essential for integrating renewable energy into the grid, particularly in the form of energy storage. When there is excess renewable energy, electrolysers can store it as hydrogen, which can be converted back into electricity when demand is high. This makes electrolysers an integral part of a more resilient and sustainable power grid.

The power generation sector is increasingly turning to electrolysers to facilitate the production of green hydrogen, which can be used for electricity generation, heating, and even industrial processes. As countries move towards achieving net-zero emissions targets, the electrolyser market will continue to grow in importance.

Industry Feedstock

Hydrogen is used as a feedstock in various industrial processes, such as refining, chemicals, and steel production. Electrolysers are critical in providing a sustainable source of hydrogen, especially as industries move away from conventional methods that rely on fossil fuels.

The decarbonization of industries like steel and cement is one of the key drivers of hydrogen demand, and electrolysers are essential to these industries’ efforts to reduce their carbon footprint. Green hydrogen produced through electrolysis is being adopted as a cleaner alternative to traditional hydrogen production methods.

Industry Energy

Industries that are energy-intensive, such as cement and aluminum, are increasingly adopting hydrogen for their energy needs. Electrolysers are integral to these efforts, producing clean hydrogen that can replace fossil fuels and reduce emissions. As companies across various sectors aim to meet stricter emissions regulations, the demand for electrolysers for industrial energy applications will continue to rise.

Regional Analysis

North America

North America, led by the United States and Canada, is at the forefront of hydrogen adoption. With strong government support for clean energy initiatives, there is a growing emphasis on the development of hydrogen infrastructure, including electrolyser systems. The transportation sector, including hydrogen-powered vehicles and refueling stations, is expected to drive significant demand for electrolysers.

Europe

Europe is a global leader in the transition to hydrogen, with several countries setting ambitious targets for hydrogen production and use. The European Union’s Green Deal and hydrogen strategy are supporting large-scale projects involving electrolysers, particularly in Germany, the Netherlands, and the United Kingdom. The European market for electrolysers is expected to expand rapidly as nations prioritize hydrogen as a key component of their decarbonization efforts.

Asia-Pacific

The Asia-Pacific region, particularly China, Japan, and South Korea, is also experiencing significant growth in the electrolyser market. These countries are investing heavily in hydrogen infrastructure, and electrolysers are a critical part of their clean energy strategies. The growing demand for hydrogen-powered vehicles, as well as industrial applications, is contributing to the increased adoption of electrolysers.

Rest of the World

Emerging markets in Latin America, the Middle East, and Africa are gradually adopting hydrogen solutions, and the electrolyser market is expected to grow in these regions as well. As these markets industrialize and focus on sustainable energy, the demand for electrolysers will increase, particularly for energy storage and industrial applications.

Competitive Landscape

The electrolyser market is competitive, with several key players dominating the market. Leading companies include Nel Hydrogen, ITM Power, Siemens Energy, Cummins Inc., and Hydrogenics. These companies are focusing on expanding their product portfolios, improving electrolyser efficiency, and exploring new markets through strategic partnerships and acquisitions.