In industries that handle large volumes of raw materials or finished goods, efficient storage and transportation solutions are critical. Flexible Intermediate Bulk Containers (FIBCs), commonly known as bulk bags, have become indispensable in this regard. These heavy-duty storage solutions provide a cost-effective, durable, and versatile option for various industrial needs. In this article, we explore the significance of durable FIBC bulk bags, their applications, and why choosing reliable Fibc bulk bag manufacturers in Ahmedabad, Gujarat, and across India is essential for ensuring quality and reliability.

What Are FIBC Bulk Bags?

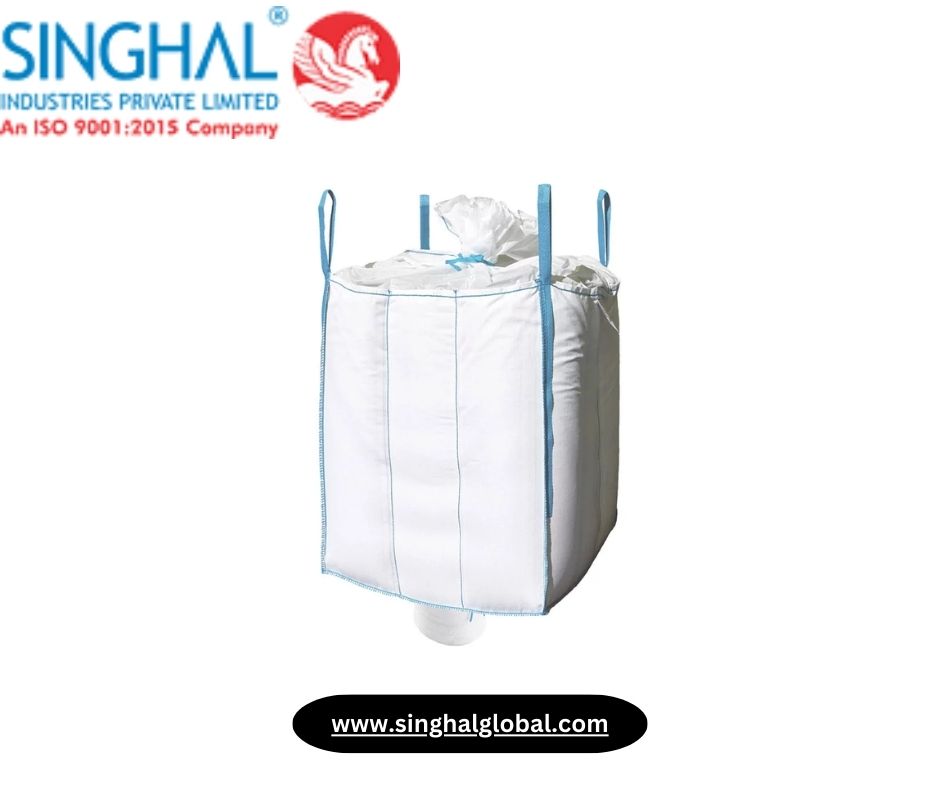

FIBC bulk bags are large, flexible containers made from woven polypropylene fabric. These bags are designed to store and transport dry bulk materials such as grains, chemicals, minerals, fertilizers, and construction materials. Their popularity stems from their ability to hold a wide range of products while offering superior durability, lightweight construction, and easy handling.

FIBCs are available in various designs, including single-loop, two-loop, and four-loop bags, and can be customized to meet specific requirements. They are also available in different sizes, with most standard bags capable of holding up to 2,000 kg of material. Additionally, FIBCs are highly efficient, reducing packaging waste and transportation costs.

Applications of FIBC Bulk Bags

FIBC bulk bags find applications across diverse industries, making them a versatile solution for heavy-duty storage. Here are some of their primary uses:

- Agriculture: Farmers and agribusinesses use FIBC bags to store and transport grains, seeds, and fertilizers. The bags protect contents from moisture, pests, and contamination, ensuring product quality.

- Construction: In the construction industry, FIBCs are used to handle and transport materials like sand, cement, and gravel. Their high load capacity makes them ideal for these heavy materials.

- Chemical Industry: The chemical sector relies on FIBC bulk bags for safe and efficient transportation of powdered and granular chemicals. These bags can be customized with liners to prevent leakage and contamination.

- Pharmaceutical Industry: FIBCs with food-grade or pharmaceutical-grade liners are used to store and transport raw materials and finished products in the pharmaceutical sector, ensuring strict hygiene standards.

- Mining: Mining companies use FIBCs for transporting ores, minerals, and other extracted materials. Their robust design ensures safe handling even in harsh environments.

Advantages of Using Durable FIBC Bulk Bags

The durability of FIBC bulk bags sets them apart from other storage solutions. Here are some key benefits:

- High Load Capacity: FIBCs can hold substantial weights, making them suitable for heavy-duty applications. They can easily support up to 2,000 kg, depending on the design.

- Customizable Design: Manufacturers can tailor FIBCs to meet specific requirements, such as size, capacity, and additional features like spouts, liners, or UV protection.

- Cost-Effective: Compared to rigid containers, FIBCs are lightweight, reducing transportation costs. Their reusability also contributes to cost savings.

- Space Efficiency: FIBCs can be folded flat when empty, saving storage space. They are also stackable, optimizing warehouse organization.

- Environmental Sustainability: Many FIBCs are recyclable, reducing environmental impact. Additionally, their reusability supports sustainable practices.

- Enhanced Safety: Designed with strong woven polypropylene fabric, FIBCs offer excellent resistance to tearing and punctures, ensuring safe handling of contents.

Choosing Reliable FIBC Bulk Bag Manufacturers

The quality of FIBC bulk bags depends significantly on the expertise of the manufacturer. It is crucial to partner with reputable Fibc bulk bag manufacturers in Gujarat, or other regions in India. Here’s why:

- Expertise and Experience: Established manufacturers have the technical expertise to produce high-quality FIBCs that meet industry standards. Their experience ensures consistent product performance and reliability.

- Customization Options: Reliable manufacturers offer customization options to meet specific needs, such as custom sizes, printing, and additional features like liners or anti-static properties.

- Quality Assurance: Trusted manufacturers adhere to stringent quality control processes, ensuring that each bag meets safety and performance criteria. They use high-grade raw materials to enhance durability.

- Compliance with Standards: Leading manufacturers comply with international standards such as ISO, BRC, and food-grade certifications, ensuring product safety and compatibility for diverse applications.

- Timely Delivery: Efficient manufacturers prioritize timely delivery, enabling businesses to meet their operational timelines without delays.

Spotlight on FIBC Bulk Bag Manufacturers in Ahmedabad, Gujarat, and India

Ahmedabad, Gujarat, has emerged as a hub for high-quality FIBC bulk bag manufacturing in India. With a strong industrial base and access to top-grade raw materials, manufacturers in this region have earned a reputation for excellence. These manufacturers cater to domestic and international markets, offering products that meet global standards.

- Ahmedabad is home to some of the most innovative FIBC manufacturers in India, known for their state-of-the-art facilities and focus on quality. They provide customized solutions tailored to specific industries.

- Gujarat, a leading industrial state, boasts a large number of FIBC manufacturers. These companies leverage advanced technology and skilled labor to produce durable and versatile bulk bags.

- Indian manufacturers are globally recognized for their competitive pricing and adherence to international quality standards. They supply a wide range of FIBCs to industries worldwide, contributing to India’s position as a key player in the global packaging industry.

Maintenance and Storage Tips for FIBC Bulk Bags

To maximize the lifespan of FIBC bulk bags, proper maintenance and storage are essential. Here are some tips:

- Store in a Dry Area: Keep FIBCs in a dry, covered space to prevent moisture damage and UV exposure.

- Avoid Overloading: Do not exceed the bag’s weight capacity to ensure safety and durability.

- Inspect Before Use: Regularly inspect bags for any signs of wear, tear, or damage before reuse.

- Clean Properly: If the bags are reusable, clean them thoroughly following the manufacturer’s guidelines to prevent contamination.

Conclusion

Durable FIBC bulk bags are a cornerstone of efficient storage and transportation in various industries. Their versatility, cost-effectiveness, and robust design make them an ideal choice for heavy-duty applications. By partnering with reputable Fibc bulk bag manufacturers in India, and Ahmedabad Gujarat, and across India, businesses can ensure they receive high-quality products tailored to their needs. As industries continue to prioritize efficiency and sustainability, the demand for FIBC bulk bags is set to grow, reinforcing their importance in the global supply chain.

Frequently Asked Questions

What materials are FIBC bulk bags made of?

FIBC bulk bags are primarily made of woven polypropylene fabric. This material is lightweight, durable, and resistant to tearing, making it ideal for heavy-duty storage and transportation.

Can FIBC bulk bags be reused?

Yes, many FIBC bulk bags are reusable, provided they are handled and maintained properly. Always check the manufacturer’s guidelines for reuse and inspect the bags for any damage before reusing them.

What industries commonly use FIBC bulk bags?

FIBC bulk bags are widely used in industries such as agriculture, construction, chemicals, pharmaceuticals, and mining. Their versatility and durability make them suitable for transporting and storing a variety of dry bulk materials.