Introduction

The benzisothiazolinone manufacturing plant project is an essential undertaking within the chemical industry, particularly in the production of biocides used in various applications. Benzisothiazolinone (BIT), primarily known for its antimicrobial properties, is widely used in the preservation of paints, coatings, adhesives, cleaning products, and other industrial and consumer goods. This Benzisothiazolinone Manufacturing Plant Project Report outlines the key considerations, from business planning and setup to production costs and market insights, for establishing a benzisothiazolinone manufacturing facility. The demand for BIT is on the rise due to its growing applications in the paints and coatings industry, making this manufacturing venture highly lucrative.

Market Overview and Demand Analysis

Benzisothiazolinone is an important preservative used in water-based products, including paints, coatings, and personal care items, which are exposed to microbial contamination during storage. Its use as a preservative in paints is a significant driver for demand, especially in regions where infrastructure development is booming. The global market for BIT is expected to grow due to increasing construction activities, heightened awareness of health standards, and the need for environmentally friendly alternatives to other chemical preservatives.

The demand for BIT is also fuelled by the increasing production of personal care and household products, as well as the rise in industrial applications. Emerging markets, particularly in Asia and Latin America, are expected to drive the demand for BIT-based products. The market is competitive, with several key players already in the market, including companies that supply raw materials such as sodium bisulfite and sodium hydroxide, which are essential in the production of benzisothiazolinone.

Get a Free Sample Report with Table of Contents@

Project Feasibility Study

A feasibility study is crucial to assess the potential success of the benzisothiazolinone manufacturing plant. This includes evaluating the technological, economic, environmental, and operational aspects of the plant. The following are essential components:

1. Raw Materials and Supply Chain

The primary raw materials for producing benzisothiazolinone are sodium bisulfite and sodium hydroxide, which react to produce the final product. The availability of these raw materials, along with the cost and quality considerations, is a key factor in determining the success of the project. Establishing strong relationships with reliable suppliers ensures a stable supply of raw materials at competitive prices.

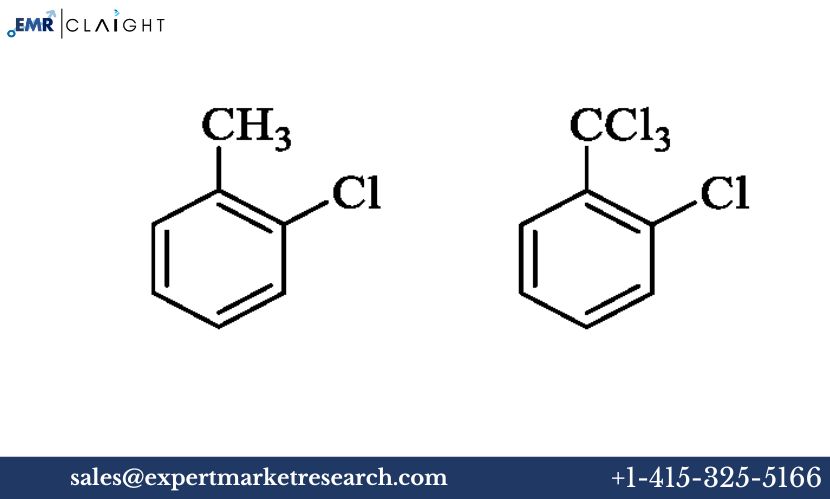

2. Manufacturing Process

The manufacturing process for benzisothiazolinone generally involves a sulfonation reaction between isothiazolinone and sodium bisulfite. The reaction is carried out under controlled conditions, and the byproducts are neutralized and removed. The production process can be optimised by selecting efficient equipment, such as reactors and separators, to reduce operational costs and improve yield.

3. Capital Investment

A significant part of the plant setup involves capital investment. This includes costs for machinery, infrastructure, and compliance with regulatory standards. Investment in R&D is also important for product innovation and improvement in production efficiency. Depending on the scale of the facility, the capital cost can vary, but an average manufacturing facility requires substantial initial funding, which could range from USD 1 million to USD 5 million.

4. Operational Expenses

Operational expenses include electricity, water, labor costs, raw material procurement, and maintenance of the production facility. For optimal financial performance, it is important to keep operational costs under control, especially energy consumption, which can be a significant cost in chemical manufacturing processes.

Site Selection and Plant Layout

Selecting an appropriate location for the manufacturing plant is critical. Proximity to raw material sources, availability of skilled labor, access to transportation networks, and favourable government policies are key factors influencing the site selection. Typically, manufacturing plants for chemical production are located in industrial zones or close to ports for easy distribution.

Key Factors for Site Selection:

- Access to raw materials like sodium bisulfite and sodium hydroxide.

- Utility availability, including power and water.

- Environmental regulations compliance.

- Logistics and transport networks for distribution.

Financial Analysis and Profitability

1. Revenue Projections

Revenue from a benzisothiazolinone manufacturing plant is primarily generated through direct sales to industries such as paints and coatings, cleaning products, and personal care manufacturers. With an average market price of USD 5-10 per kilogram for benzisothiazolinone, the revenue potential can be significant, especially with a high production output.

2. Cost Breakdown

The costs for establishing and operating a benzisothiazolinone manufacturing plant include:

- Fixed costs: This includes investment in machinery, building, and licensing.

- Variable costs: Costs associated with raw materials, labor, and utilities.

The break-even point for such a plant typically occurs within 3-5 years, depending on the scale of the operation and the efficiency of the business model.

Regulatory Compliance and Environmental Impact

Operating a chemical manufacturing plant involves compliance with local and international environmental regulations. Regulations like the REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) in the European Union and EPA (Environmental Protection Agency) standards in the United States govern the production and disposal of hazardous chemicals. Moreover, the plant must have a robust system in place for waste management and emissions control.

Environmental Concerns

Benzisothiazolinone, while effective as a biocide, can be toxic to aquatic life if released into water bodies. Therefore, stringent wastewater treatment processes must be incorporated to prevent contamination. The use of ozone treatment for effluent water to degrade BIT and its byproducts is one way to manage toxicity .

Technology and Innovations

Incorporating modern technology is crucial for the success of the plant. Advancements in automation, energy-efficient reactors, and environmental control technologies can greatly improve the efficiency and sustainability of the manufacturing process. Some companies are even exploring the use of biocatalysts for more sustainable production methods.

Risk Assessment

A thorough risk assessment helps in identifying potential challenges. Key risks in this project include:

- Fluctuations in raw material costs: Prices of sodium bisulfite and sodium hydroxide can fluctuate based on market conditions.

- Regulatory changes: Environmental regulations can change, requiring additional investments in compliance technologies.

- Market competition: Other manufacturers may emerge, reducing market share.

FAQs

1. What is the main use of benzisothiazolinone?

Benzisothiazolinone is mainly used as an antimicrobial agent in paints, coatings, adhesives, and cleaning products.

2. What are the raw materials required for benzisothiazolinone production?

The primary raw materials are sodium bisulfite and sodium hydroxide.

3. How much does it cost to set up a benzisothiazolinone plant?

The initial capital investment can range from USD 1 million to USD 5 million, depending on the scale of production.

4. What are the environmental concerns related to benzisothiazolinone?

Benzisothiazolinone can be toxic to aquatic life, necessitating wastewater treatment systems to manage its disposal.

5. What is the market potential for benzisothiazolinone?

The market for benzisothiazolinone is growing, particularly in the paints and coatings industry, driven by increasing industrial activities.

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: [email protected]

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au