Content

The global ceramic textile market is gaining significant traction due to its excellent thermal resistance, lightweight nature, and superior insulation properties. Ceramic textiles, made from alumina-silica ceramic fibers, are widely used in high-temperature applications across various industries such as metallurgy, petrochemicals, aerospace, and fire protection. These materials offer exceptional resistance to heat, fire, corrosion, and thermal shock, making them a preferred choice for applications involving extreme conditions.

Market Overview

In 2024, the global ceramic textile market was valued at approximately USD 2.6 billion and is projected to reach USD 4.3 billion by 2030, growing at a compound annual growth rate (CAGR) of 8.7%. The surge in demand for energy-efficient insulation materials and growing environmental concerns are key drivers fueling this market’s growth. As industries move toward sustainability, the role of ceramic textiles in energy conservation, worker safety, and emission control becomes increasingly critical.

Key Market Drivers

-

Growing Demand in Industrial Insulation

Ceramic textiles are widely used in industrial furnaces, kilns, boilers, and other high-temperature equipment due to their superior insulation capabilities. As energy costs rise and industries seek to improve thermal efficiency, ceramic textiles offer a reliable solution for reducing energy loss. -

Expansion of the Petrochemical and Refining Sector

The petrochemical industry, which requires insulation materials for heat containment and personnel protection, significantly contributes to the demand for ceramic textiles. With ongoing capacity expansions and new plant setups, especially in Asia-Pacific and the Middle East, the need for high-performance textiles is increasing. -

Stringent Fire Safety Regulations

Enhanced fire safety regulations across the globe, especially in developed markets, have led to the increased adoption of fire-resistant materials. Ceramic fabrics and ropes are widely used in fire barriers, fireproof blankets, and safety clothing due to their flame retardant properties. -

Technological Advancements

Continuous innovations in textile manufacturing techniques have led to the development of more flexible, durable, and lightweight ceramic fabrics. These improvements have expanded their application scope in aerospace, defense, and automotive heat shielding.

Market Segmentation

By Product Type:

-

Rope – Used for sealing, gasketing, and insulation.

-

Cloth – Ideal for welding blankets and curtains.

-

Tape – Used for wrapping pipes, cables, and exhaust systems.

-

Sleeving – Common in aerospace and automotive for thermal protection.

By Fiber Type:

-

Refractory Ceramic Fiber (RCF) – Traditional choice with strong thermal performance but facing environmental concerns.

-

Alkaline Earth Silicate (AES) Wool – More eco-friendly alternative, increasingly preferred in Europe.

-

Others – Including specialty composite ceramic fibers.

-

Petrochemical and Refining

-

Aluminum and Steel

-

Power Generation

-

Aerospace and Defense

-

Automotive

-

Construction

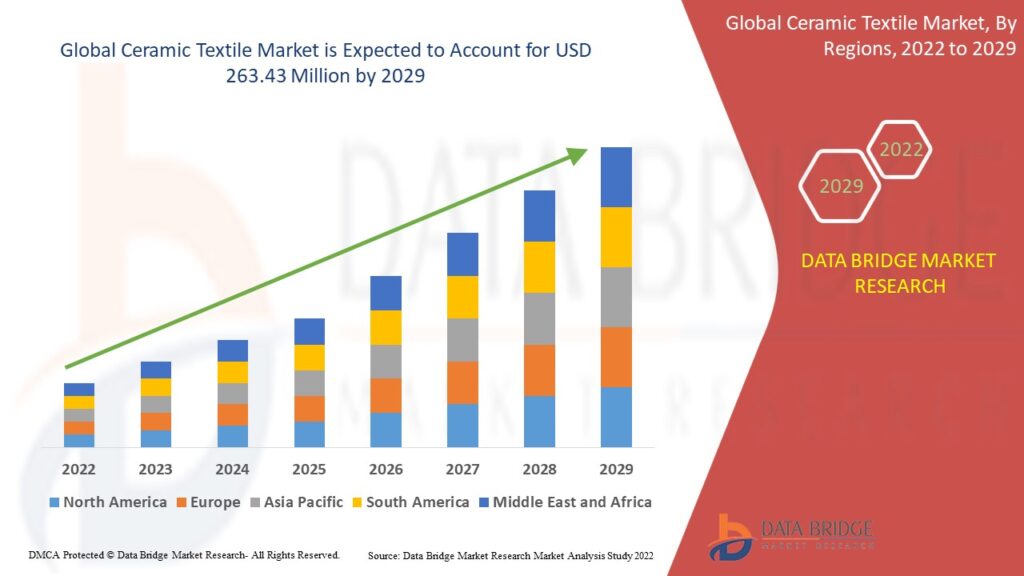

Regional Analysis

North America and Europe are mature markets, driven by strict energy efficiency standards and fire safety regulations. The United States, in particular, leads the market with high consumption in the oil & gas, aerospace, and industrial manufacturing sectors.

Asia-Pacific is the fastest-growing region due to rapid industrialization, increasing infrastructure development, and a growing emphasis on energy conservation. Countries like China, India, and Japan are witnessing rising adoption of ceramic textiles in both traditional manufacturing and emerging technologies.

Middle East & Africa is also showing potential, especially in petrochemical and construction sectors where high-temperature insulation is crucial.

Competitive Landscape

The global ceramic textile market is moderately consolidated with a few major players holding significant market shares. Companies are focusing on product innovation, sustainability, and geographical expansion to strengthen their market positions.

Key players include:

-

3M Company

-

Unifrax LLC

-

Ibiden Co., Ltd.

-

Isolite Insulating Products Co., Ltd.

-

Zircar Ceramics, Inc.

-

Morgan Advanced Materials

-

Rex Materials Group

-

Luyang Energy-Saving Materials Co., Ltd.

Recent Developments

-

3M introduced advanced ceramic fiber cloths with improved flexibility for aerospace insulation applications.

-

Unifrax expanded its range of low bio-persistent fiber textiles for more eco-conscious users.

-

Luyang increased its production capacity in China to meet rising regional demand.

Challenges

Despite strong growth prospects, the ceramic textile market faces some challenges:

-

Health and Environmental Concerns: Certain ceramic fibers, especially RCFs, are being scrutinized due to health risks associated with airborne fiber exposure. This has led to regulatory restrictions, particularly in the EU.

-

High Cost of Raw Materials: The specialized nature and high purity of materials used in ceramic textiles make them relatively expensive.

-

Substitution Risk: In certain low-heat applications, cheaper alternatives like fiberglass and mineral wool may replace ceramic textiles.

Future Outlook

The future of the ceramic textile market looks promising as industries increasingly prioritize energy efficiency, safety, and regulatory compliance. With the growing push toward green manufacturing and sustainable insulation, the demand for non-toxic, recyclable, and energy-efficient ceramic textiles is set to rise.

Technological innovations, such as nano-ceramic coatings and hybrid ceramic composites, are expected to open new avenues for product application and performance. Moreover, increased adoption in electric vehicles and battery technologies could present further growth opportunities in the automotive sector.

In conclusion, the ceramic textile market is poised for steady expansion driven by industrial demand, regulatory standards, and technological innovation. As end-users seek robust, safe, and sustainable insulation solutions, ceramic textiles will remain a vital material across diverse high-performance applications.

Get more Details

https://www.databridgemarketresearch.com/reports/global-ceramic-textile-market