In the food and beverage industry, cleanliness, safety, and reliability are very important. Every part of the system, from machines to small components, must work well and follow strict hygiene standards. One such important part used in these industries is the air header. This device helps control and distribute compressed air to different points in the system.

In this blog, we will understand what air headers are, why they are useful in food and beverage processing, and what an air header manufacturer usually offers to support this industry.

What is an Air Header?

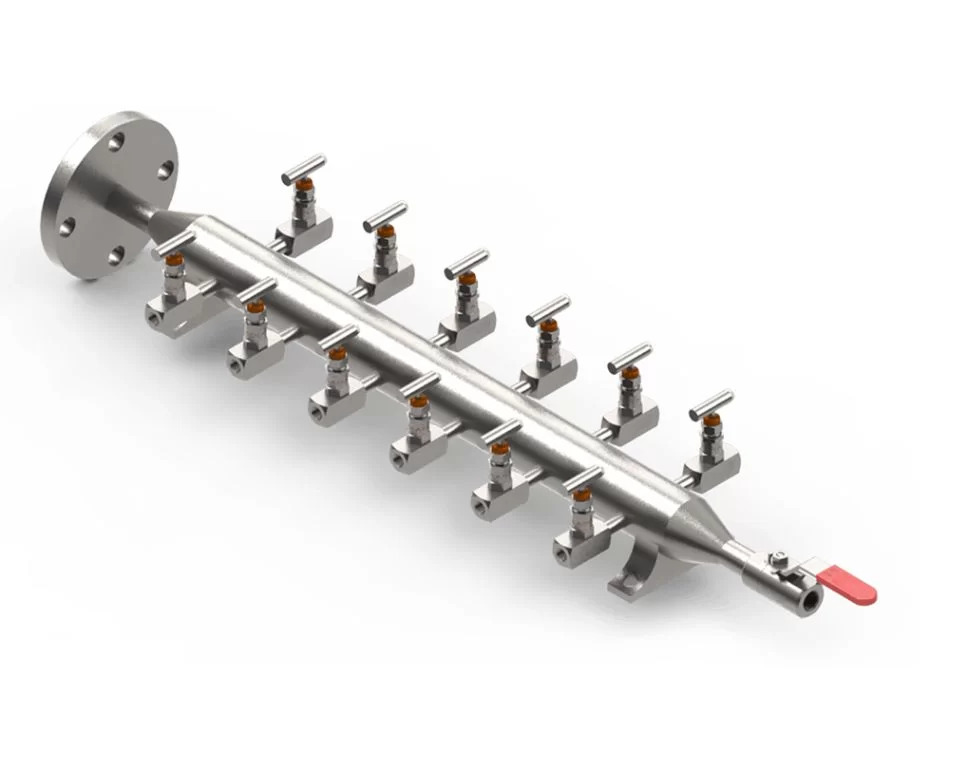

An air header is a device used to distribute compressed air from a single source to multiple points. It is usually a pipe or a steel box fitted with several outlets, each connecting to a different air tool or system. Air headers are often used in industries where multiple pieces of equipment need to be powered by compressed air.

They are made using strong and corrosion-resistant materials like stainless steel. This is especially important in food and beverage processing, where cleanliness and hygiene are a must.

Why Are Air Headers Important in Food and Beverage Processing

The food and beverage industry has very strict rules for safety, cleanliness, and efficiency. Air headers play a key role in meeting these needs.

Here are a few reasons why air headers are used in this industry:

1. Clean Compressed Air Distribution

Air headers help supply clean compressed air to different areas in a processing plant. Compressed air is used for many jobs, including operating valves, moving ingredients, or cleaning machines. With an air header, one source can supply multiple destinations, saving time and effort.

2. Improved Safety and Hygiene

In food and beverage production, it’s very important to avoid contamination. Air headers made from stainless steel are easy to clean and don’t rust. This makes them perfect for places where hygiene matters.

3. Better Control and Efficiency

With multiple outlets, air headers allow better control over compressed air flow. Operators can connect or disconnect equipment quickly. This leads to better energy management and reduces waste.

4. Reduces Pipe Clutter

Instead of using many air pipes running across the factory, an air header can centralize the system. This keeps the workspace tidy and reduces the risk of accidents.

Uses of Air Headers in Food and Beverage Industry

In food and beverage plants, air headers are used in many areas. Some common uses include:

– Valve Operation

Air headers help run pneumatic valves used in food and beverage machines. These valves need a steady supply of compressed air to open or close during processing.

– Cleaning Equipment

Compressed air is often used to clean parts of machines that cannot be washed with water. Air headers make this possible by delivering air to cleaning tools or blow guns.

– Packaging Systems

Air headers are used in machines that package food items. Compressed air helps move products, fill containers, or seal packets.

– Automation Systems

Modern food plants have many automatic machines. These machines use pneumatic power, which is delivered through air headers.

What an Air Header Manufacturer Offers

An air header manufacturer plays a key role in making sure that the right type of air header is available for different industrial uses. Manufacturers design, build, and supply air headers that fit the needs of the food and beverage industry.

Here’s what a reliable air header manufacturer usually offers:

1. Wide Range of Designs

Manufacturers offer air headers in many shapes and sizes. Some are designed like straight pipes, while others are box-type. This helps users pick the right design based on space and function.

2. Strong and Safe Materials

Since food and beverage processing needs high levels of hygiene, manufacturers use strong and clean materials like stainless steel. These materials resist corrosion and are safe for use around food.

3. Multiple Outlet Options

Air headers come with different numbers of outlets. Manufacturers can offer 4, 6, 8, or even 12 outlets depending on how many machines need to be connected.

4. Custom-Made Solutions

Many manufacturers provide custom-built air headers. If a company has special needs — like a different size, shape, or pressure rating — the air header can be made just for them.

5. Testing and Quality Checks

A trusted air header manufacturer always tests their products before delivery. This includes pressure testing, leak testing, and quality inspection to make sure the air header is safe and reliable.

6. Easy Installation Support

Some manufacturers offer installation help or provide manuals and instructions. This makes it easier for users to set up the air header quickly.

7. Fast Delivery and Bulk Supply

Food and beverage companies often need air headers fast. Manufacturers keep stocks ready or provide quick production services to meet urgent demands. They also handle bulk orders for large projects.

Features to Look for When Choosing an Air Header Manufacturer

If you are looking for an air header manufacturer, here are some important things to check:

-

Use of high-quality materials (especially stainless steel)

-

Multiple design options

-

Ability to provide custom solutions

-

Strict testing and inspection

-

Fast delivery and support

-

Experience in supplying to the food and beverage sector

Choosing the right manufacturer means better product quality, less downtime, and safer food production.

Benefits of Using Air Headers from a Trusted Manufacturer

When you use air headers from a reliable air header manufacturer, your plant gets:

-

Longer equipment life

-

Reduced maintenance needs

-

Better hygiene control

-

Smooth air supply without leaks

-

Lower chance of system failure

Conclusion

Air headers may look simple, but they are an important part of food and beverage processing systems. They help distribute clean and reliable compressed air to different machines, valves, and tools. Their use improves hygiene, safety, and efficiency in production plants.

A trusted air header manufacturer can offer strong, clean, and well-designed products that match the needs of modern food processing units. Whether it’s standard or custom-built, the right air header ensures smooth operation and helps maintain high standards of quality and cleanliness in the plant.