As 3D technology continues to evolve, 3D scanning services have become a powerful tool in industries like manufacturing, design, healthcare, and heritage preservation. Whether you’re reverse-engineering a product, capturing a prototype, or digitizing complex geometries, 3D scanning provides the accuracy and detail needed for high-quality results.

But not all 3D scanning methods are the same. Choosing the right one depends on your project’s size, surface type, required precision, and speed. In this guide, we’ll explain the most common types of 3D Scanning Services—including laser scanning, structured light, and more—so you can make the right choice.

1. Laser 3D Scanning

How it works:

Laser scanning uses a focused laser beam to measure the distance between the scanner and the object’s surface. The scanner captures thousands (even millions) of data points, creating a detailed “point cloud” that maps the shape and size of the object.

Best for:

-

Large objects like vehicles or buildings

-

Industrial applications and plant layouts

-

Capturing fine details on rough or uneven surfaces

Advantages:

-

High precision and long-range capabilities

-

Works well outdoors and in varying lighting

-

Great for complex, large-scale structures

Limitations:

-

Can be expensive

-

Not ideal for reflective or transparent surfaces without preparation

2. Structured Light Scanning

How it works:

Structured light scanners project a series of light patterns (grids or stripes) onto an object. Cameras detect the distortion of the patterns on the object’s surface to reconstruct the 3D shape.

Best for:

-

Medium to small objects

-

Sculptures, consumer products, or human body parts

-

High-detail reverse engineering

Advantages:

-

Very accurate and fast

-

Non-contact and safe for delicate items

-

Excellent for texture capture and color detail

Limitations:

-

Sensitive to ambient lighting

-

Less effective on shiny or dark surfaces unless treated

3. Photogrammetry

How it works:

Photogrammetry uses 2D photographs taken from multiple angles to reconstruct a 3D model. Specialized software aligns and processes the images to generate a textured 3D mesh.

Best for:

-

Artistic and cultural heritage objects

-

Environments like terrains or building exteriors

-

Budget-friendly scanning needs

Advantages:

-

Inexpensive (can even use a smartphone or DSLR)

-

Captures realistic textures and colors

-

Great for outdoor or large-area scans

Limitations:

-

Lower accuracy than laser or structured light

-

Processing time can be long

-

Requires consistent lighting and clear images

4. Contact 3D Scanning (CMM Scanning)

How it works:

Contact scanning involves a coordinate measuring machine (CMM) that physically touches points on an object to measure geometry. Though slower, it’s extremely accurate and often used in quality control.

Best for:

-

High-precision inspection tasks

-

Dimensional verification of machined parts

-

Metrology labs and regulated industries

Advantages:

-

Extremely accurate

-

Not affected by lighting or surface reflectivity

-

Ideal for hard, rigid surfaces

Limitations:

-

Very slow and limited to accessible areas

-

Can’t be used on delicate or soft objects

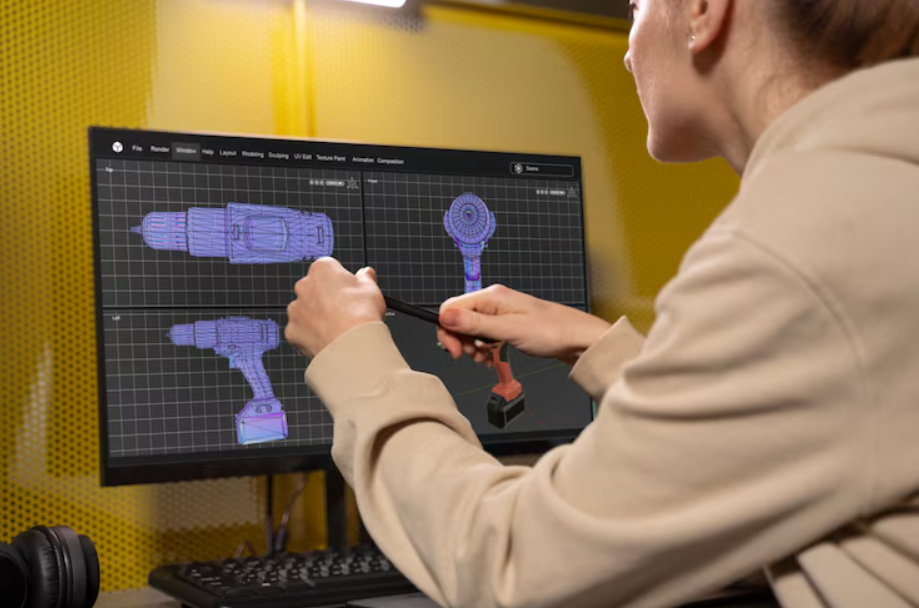

5. Handheld 3D Scanners

How it works:

Handheld scanners use a combination of structured light or laser technology in a portable format. The operator moves around the object to capture it from all sides.

Best for:

-

On-site scanning

-

Objects that are difficult to transport

-

Flexible scanning of complex shapes

Advantages:

-

Portable and user-friendly

-

Scans in real-time

-

Adaptable to various object sizes

Limitations:

-

Operator movement can affect accuracy

-

Resolution may not match fixed scanning systems

Which 3D Scanning Service Is Right for You?

Choosing the right 3D scanning method depends on your specific needs. Here’s a quick guide:

| Use Case | Recommended Scanning Type |

|---|---|

| Industrial design, reverse engineering | Laser or Structured Light |

| Small, detailed objects | Structured Light |

| Outdoor environments or large areas | Laser or Photogrammetry |

| Budget-conscious projects | Photogrammetry |

| Dimensional inspection | Contact / CMM |

| On-the-go flexibility | Handheld Scanner |

Final Thoughts

As the demand for precision and digitization grows, 3D scanning services are becoming essential across a wide range of industries. Whether you need high-detail scans for engineering, textured models for gaming, or accurate replications for manufacturing, there’s a scanning method built for the job.

By understanding the strengths and limitations of laser, structured light, photogrammetry, and other scanning types, you can confidently choose the right service for your next project—and ensure that every detail is captured with precision.